Electronic nose nanosensor could boost traceability efficiency

A dramatic increase in traceability efficiency could result from the recent agreement signed for product development and distribution of an electronic nose nanosensor deployed at University of California.

This nanosensor, that already exists, will be further refined to detect deadly pathogens including toxic pesticides in the global food supply chain, with direct impact in traceability in order to detect a potential outbreak source.

This nanosensor, that already exists, will be further refined to detect deadly pathogens including toxic pesticides in the global food supply chain, with direct impact in traceability in order to detect a potential outbreak source.

The electronic nose trading company, Nano Engineered Applications Inc. (NEA), an ieCrowd company, signed a multi-phased long term agreement with a collaborator that is working directly with ieCrowd’s team members and the professor in charge of the sensor develoment. This is the first time the sensor will be customized for food safety measurements, although it is already been used in a set of products for industries such as industrial premises for gas leaks or combustion emissions detection, homeland security for bio-terrorism warning systems and the military for detecting chemical warfare agents.

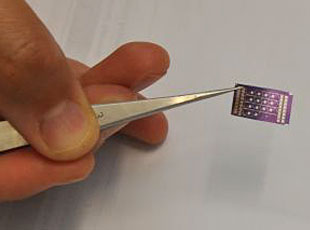

The nanosensor uses functionalized carbon nanotubes, which are 100,000 times finer than human hair, to detect airborne toxins down to the parts per billion level.

“This collaboration will, when successful, usher in a new era of transparency and efficiency for measuring the level of pesticides and other chemicals in plants we use for food and medicine,” said Stephen F. Abbott, president of NEA. “Our work will also make the technology available to a broad number of applications that are important for a range of new and existing industries globally.”

The agreement is comprised of two phases: first, establishing efficacy of NEA’s sensors with these volatile organic compounds; and second, should phase one be successful, the development of hand-held products to detect volatile organic compounds.

The success of this project would impact seriously in food traceability efficiency and timing in case of outbreak as long as this electronic nose have been properly used and their measurements recorded at every step in the production chain from farm to fork, because it would point directly to the first step where the contamination took place at the very first time it happens.