Food for Thought

The Food Safety Modernization Act mandates new standards and documentation for traceability and verification of the cold chain

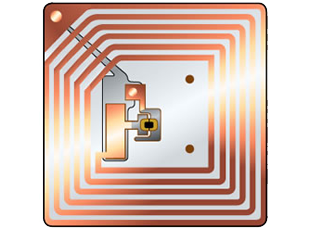

Technology enhances practices in many supply chains and can enhance the food distribution chain as well. The basic warehouse functions of receiving, stacking, picking, staging and shipping are shared among most operations. Bar codes and scanners smooth and speed processes. Radio frequency identification (RFID) tags and wireless networks are adding data to inventory systems and increasing the velocity of each warehouse activity. It is not just goods that must move at high velocity—data must flow even faster up and down the supply chain.

Technology enhances practices in many supply chains and can enhance the food distribution chain as well. The basic warehouse functions of receiving, stacking, picking, staging and shipping are shared among most operations. Bar codes and scanners smooth and speed processes. Radio frequency identification (RFID) tags and wireless networks are adding data to inventory systems and increasing the velocity of each warehouse activity. It is not just goods that must move at high velocity—data must flow even faster up and down the supply chain.

Perishable food adds complexity and makes the food distribution facility a fluid environment, also known as the cold chain. Facilities must be able to receive, document, and ship both perishable and non-perishable items with tremendous velocity in variable temperatures.

The Food Safety Modernization Act (FSMA) was signed in January 2011. It is considered the most sweeping overhaul of food regulations in decades and puts the noble goal of reducing food-borne illness into operation at every step of the food chain. The act compels food companies to constantly assess risk in their operations and verify the safety of any food entering the distribution chain. That data must be available to the Food and Drug Administration (FDA), which has greater authority for inspections and records access on any food item—not just those that are suspected of causing a health concern.

Discovering and implementing the best practices for a given facility is a high priority to speed compliance reporting and records keeping in the cold chain. The FSMA is a timely piece of legislation, based on widespread media coverage of food recalls and foodborne illnesses. FSMA’s goals are a healthier, safer, more responsive food system for society and mandates new standards—and documentation—for traceability and verification of the cold chain from farm to fork, and mobile technology can help facilitate the process.

Traceability

Traceability is increasingly important to food service companies’ customers. According to BBC Radio, consumers are 12 percent more likely to buy food that can be traced to its source, a fact reflecting consumer concerns about the food system. Food industry managers are seeing those concerns reflected in the customer base as well. Nearly a third of the food service executives polled by Voxware in a 2011 study reported that their customers were frequently or urgently asking about traceability compliance, and easily half of customers were asking at least occasionally.

Traceability also increases the speed of response when an outbreak occurs. Documenting food shipments between the farm and the consumer—whether through a grocery store or a restaurant at the retail level—makes it easier to take specific action to recall tainted food commodities before they are consumed by others. Swift identification of the sources of tainted food also preserves the integrity of the rest of the goods in the chain so they can continue flowing. Preserving that flow supports profitability for the industry and cost control for consumers.

Food needs to be properly tracked from where it is produced through potentially numerous parallel distribution channels. In focusing on the prevention and detection of food safety issues, cold chain compliance is more critical than ever. Monitoring the condition of the product with new mobile technology allows for much better compliance with cold chain requirements. This could also mean altering some contracts to ensure that a vendor captures the required data.

Cold Chain Monitoring

RFID readers, scanners, mobile computers, radios and wireless networks work together within the unique environment of cold chain through perishable food production, distribution, transportation, storage and sale.

Implementing a scalable, electronic traceability system requires bar coding at each step in the chain with RFID tagging. Data collected must certify the origin of the food product, the time it spent in the supply chain, and the conditions under which it was stored and transported. From there, the tags can be scanned using pallet scanners or handheld RFID scanners. Workers armed with mobile computers or enterprise-grade tablets can monitor and track data in real time. Two-way radios can expedite communications, getting the right worker to the right place. Vehicle-mounted computers on forklifts can help direct drivers to the right refrigeration unit. A robust wireless network can enable all these devices both inside and outside the warehouse.

FSMA requires documentation of the chain of custody for perishable food items. Perishable food has a definite shelf life and demands special handling at every step of the distribution process. Food industry executives are already sensitive to the demands of the cold chain. For manufacturers who distribute their product through wholesale distributors or directly to retailers utilizing direct store delivery (DSD) practices, even minor disruptions in the cold chain can affect food’s shelf life and possibly its safety. Monitoring and operational best practices must be established around the container, transportation systems and in-facility refrigeration systems.

Mobile technology can help create a streamlined environment in which issues can be promptly remedied and food-tracking information is available in real time, helping prevent any issues in food safety. Let’s take a look at two specific examples: containers and transportation.

Container Safety Monitoring

To document the preservation of the cold chain, containers must be monitored in new ways. Containers must be tracked as units of one rather than by pallets, lots or other aggregated units of the past. Correspondingly, the integrity of the cold chain must be verifiable down to each container. This requires sensors within the container that report on the container’s status. Advances in scanning techniques also make it possible to place sensors directly on sensitive foodstuffs, such as meats, to improve the granularity of the data captured. This data capture must also flag issues in cold containment so they can be addressed quickly before any risk of contamination is approached. Workers can track this information in real time on their mobile devices, enabling that quick response.

Transportation and Refrigeration Units

From the moment food of any kind leaves the farm, the clock is ticking on its freshness and shelf life. Modern refrigeration extends that life, but the integrity of the refrigerated environment must be maintained and, under FSMA, documented. Sensors can enable machines to report status so managers can intervene long before the cold chain is broken. Monitoring practices must include watching for temperature anomalies and plans for action when issues are identified.

Workers can be quickly dispatched to repair a malfunctioning machine, and get it up and running to maintain capacity. The technicians can bring up machine schematics on their enterprise-grade tablet or head-mounted computer, and make the right repairs quickly. In addition, a worker can scan the food and a supervisor can dispatch the right team to discard any damaged food in real time.

The FSMA recognizes the centrality of the food system in our society and was designed to ensure its integrity. Food industry management can be part of that solution by deploying the technologies that drive best practices for handling both perishable and non-perishable goods. Sensor networks built on top of a foundation of bar code scanning and RFID tags can create a seamless solution from farm to plate, and drive best practices around the data they produce. With mobile, wireless and automated data capture technologies, which are designed specifically for the unique demands of the cold chain, companies at any point of the food supply chain can meet the goal of protecting consumers, while also protecting their own brands and, ultimately, their productivity and profitability.

Source: worldfishing.net