Food Traceability and RFID

RFID technology gains ground with the new new rules proposed by FDA.

The new rules proposed by the FDA for the food and beverage sector last week require importers to enhance their responsibility for the food they import to the US, essentially shifting the burden of inspection from the FDA to private companies.

The new rules proposed by the FDA for the food and beverage sector last week require importers to enhance their responsibility for the food they import to the US, essentially shifting the burden of inspection from the FDA to private companies.

As a result, importer companies will need to enforce the control on food to ensure that it is not contaminated and to provide fast backward traceability for every imported product they serve.

This would have been almost impossible in practice in the past, when human workers in foreign countries would have to scan personally unique bar codes on product lots coming from different sources, many of which would have been rendered unusable because of mud.

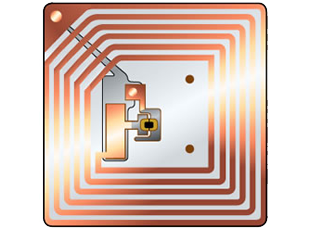

Nowadays we can automate data collection through RFID technology. We can read passive tags on plastic containers as the containers are loaded onto trucks, while linking GPS to those reads, so that we can record the source of all the products. Battery-assisted temperature sensors, meanwhile, can assure that the goods are stored at the proper temperature as they move through the supply chain.

The FDA will not mandate a specific technology however, and for farmers the use of RFID technology could become expensive, but for costs reduction a solution could be, for example, a pallet-level traceability provided by RFID temperature-sensing tags.

Bearing in mind the high cost of product recalls, that could be devastating for both producers and distributors, having the capacity to reduce a recall to a pallet level with the application of RFID technology would be probably cost efficient in the medium term, and would save much money in the long term. What’s more, it could help protect the public from contaminated foods, and help food marketers avoid costly recalls that would damage not only their funding but also their reputation.