To-Jo improves tracing and packing to provide best quality mushrooms

By using a real time PTI tracing system we can more effectively manage our labor costs and increase our profitability.

“We have exhibited at the New York Produce Show since its inception,” said Peter Wilder, marketing director for To-Jo Mushrooms in Avondale, PA. “Our experience at the previous shows was really great. The show has grown tremendously over the past few years, and is turning into a ‘must attend’ event. It gives us at To-Jo an opportunity to engage with many of our existing customers, while being afforded a chance to network with new potential retail and foodservice partners.”

“We have exhibited at the New York Produce Show since its inception,” said Peter Wilder, marketing director for To-Jo Mushrooms in Avondale, PA. “Our experience at the previous shows was really great. The show has grown tremendously over the past few years, and is turning into a ‘must attend’ event. It gives us at To-Jo an opportunity to engage with many of our existing customers, while being afforded a chance to network with new potential retail and foodservice partners.”

To-Jo Mushrooms will be exhibiting at the NYPS at Booth No. 277, and will have representatives from its executive, sales and marketing team on hand to meet and greet visitors.

Wilder noted that with so many shows and events on the calendar, the NYPS has found a slice of time that seems to work for everyone.

‘To-Jo’s’ Fresh Portabella Sliders.“This is evidenced by the growth of the show in recent years,” he said. “We also like to keep close tabs on our production projections for the coming year, so being held in December allows us to better understand the availability of product as we approach prospects on instituting new programs.

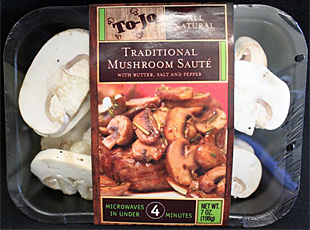

“In the midst of the busy holiday season, we are looking to highlight our 20-ounce and 24-ounce retail club packs at the New York Produce Show,” Wilder continued. “We will also be featuring our value-added products, such as our seven-ounce packs of microwave mushrooms, and our ‘Bella Blended’ Mushroom Meatballs for our foodservice customers.”

He added that To-Jo was recently written up in Fresh Cut Magazine highlighting its partnership with SG systems and the “Vantage” Traceability PTI Software it currently uses in its fresh packing operations.

“By using a real time PTI system we can more effectively manage our labor costs and increase our profitability,” noted Wilder. “Knowing where the product came from, when it was picked and where it’s going allows us to expedite a response to any potential issues that may arise. To-Jo prides itself on food safety and is continually looking at ways to improve and enhance its stellar record and SQF Level 3 Excellent Rating.”

Wilder said that To-Jo is sending a shout-out of congratulations to the company’s inside sales manager, Mike Lamson, on completing the PMA Emerging Leaders Program, which culminated at the recent PMA Fresh Summit in New Orleans.

“Having young talent engaged and interested in the industry is the best way to keep us energized and poised for growth,” said Wilder.

To-Jo is continually improving its Fresh Packing facility.

“These efforts ensure that we can provide our customers with the highest quality mushrooms in the industry,” said Wilder.

Four generations of the D’Amico family have grown mushrooms in southeastern Pennsylvania. Joseph A. D’Amico began growing mushrooms in 1932, focusing his efforts on the fresh market during a time where other mushroom growers were predominantly selling to canneries. In doing so, he carved out a niche for the small farm.

Today, fourth generation Tony and Joe D’Amico oversee the business. The brothers have grown To-Jo considerably by introducing new products and sustainable programs of which retailers and consumers respond. The company is diversified into four business operations: To-Jo Fresh distributes white, brown, and specialty mushrooms in foodservice and retail packs under “To-Jo” and other brands; Brownstone Mushrooms is the growing operation; To-Jo Transportation manages logistics with the company-owned truck and trailer fleet and; To-Jo Food Products, which manufactures value-added mushroom products for retail under “Nita’s Nicest” and “To-Jo” brands, as well as the Back-of-the-House brand for foodservice and ingredient customers.

Today, To-Jo is one of the largest fresh mushroom producers in the United States with its current weekly production approximately 750,000 pounds.

It offers over 200 fresh items to meet consumer demand as well as an extensive line of processed products. Besides its Avondale headquarter location, it has a second distribution center in Little Rock, AR.

Source: producenews.com